Product description: Irradiation Cross-linked Halogen-free Flame Retardant Polyolefin

Main application: Electronic wires, automotive wires, etc.

Flammability rating: Passed VW-1

Temperature class: 105℃

Features: Excellent mechanical properties, electrical properties, flame retardant performance, and processing performance. Comply with UL1581, flame retardant through VW-1, used in high flame retardant cable field.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

EP8400X105VWB temperature resistance 105℃ ,with excellent Mechanical properties, electrical properties, flame retardant performance and processing performance. The flammability reach UL1581 VW-1, suitable for high flame retardant occasions.

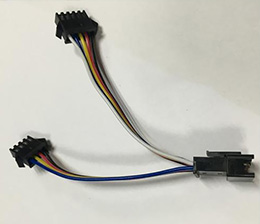

Wire & Cable

Application: Electronic wires, automotive wries, etc.

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

LSZH FRPE

Recommended Irradiation Dose: 8-10Mrad

Temperature: 105°C

Packing/Storage: 25kg/package; Transport as general chemicals. Keep it dry, in cool place and avoid direct sunlight.

| Properties | Test Standards | Units | Irradiation Cross-linked HFFR Polyolefin(VW-1) | |

| Density | ASTM D-792 | g/cm3 | 1.03±0.03 | |

| Tensile Strength | IEC 60811-1-1 | MPa | >11.0 | |

| Elongation | % | >200 | ||

| Tensile Strength After Irradiation | Cable standard | Mpa | >13.0 | |

| Elongation After Irradiation | % | >200 | ||

| Aging136℃×168h | Tensile strength retention | Cable standard | % | >90 |

| Elongation retention | % | >90 | ||

| Shore Hardness A | ASTM D 2240 | -- | 94±3 | |

| Shore Hardness D | ASTIM D 2240 | -- | 38±3 | |

| Brittle temperature | IEC60811-1-4 | ℃ | -25 | |

| Dielectric | IEC60243 | kV/mm | 25 | |

| Resistivity at(20℃) | IEC60167 | Ω·cm | >1.0×1012 | |

| Flammability | UL1581VW-1 | -- | PASS | |

Extrusion Recommendation

| Drying/Time | Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 85℃(2 hours) | 185℃ | 182℃ | 182℃ | 172℃ | 170℃ | 140℃ |

Remark: The above laboratory test data are just for reference only; It's not a basis for quality assurance.

Electronic Wire——XLPE Product

Electronic Wire——XLPE Product

Automobile Wire——XLPE Product

Automobile Wire——XLPE Product

Caros clientes, não se preocupem com as cores dos seus produtos, a POLYROCKS possui um departamento profissional de correspondência de cores, fornecendo um serviço gratuito de correspondência de cores. Quaisquer requisitos de cor, por favor, entre em contato conosco por e-mail: sales@polyrocks.com .

O foco da POLYROCKS é fornecer serviço pré / pós-venda imediato, temos engenheiros de moldagem por injeção profissionais e engenheiros de serviço técnico para fornecer informações precisas e serviço oportuno. Qualquer dúvida ou necessidade, entre em contato conosco por e-mail: sales@polyrocks.com .

Qualquer dúvida sobre compras, bem-vindo ao entrar em contato com nosso serviço ao cliente, ajuda será fornecida por eles.

Copyright © POLYROCKS CHEMICAL CO., LTD. Todos os direitos reservados |

Mapa do site

| Distribuído por

CONTATE-NOS

FORMULÁRIO DE INQUÉRITO RÁPIDO

*Indique campos obrigatórios