Product description: UV cross-linked low smoke halogen-free flame retardant PE

Main application: Color cable only (not available in black)

Flammability rating: Passed IEC60332 single cable vertical burning, C-type bunch burning test

Temperature class: 105℃

Features: Excellent mechanical properties, electrical properties,flame retardant performance and processing performance. Burning without halogen acid gas, very little releasing of toxicity and corrosion gas, and with little smoke.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us

EP8400X105J-1 temperature resistance is 105℃, with excellent Mechanical properties, electrical properties, flame retardant performance and processing performance.

XLPE Granule

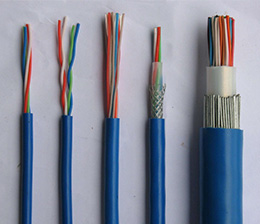

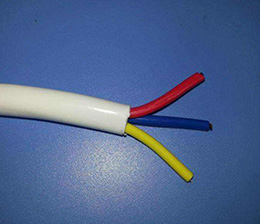

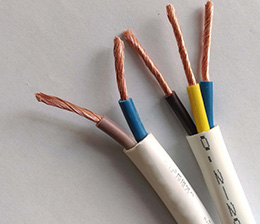

Indoor Colored Wire——XLPE Product

Wire & Cable

Application: Color cable only (not available in black)

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

XLPE

Flame retardant performance: Meet the requirements of IEC 60332 single cable vertical burning.

Temperature: 105°C

Characteristic: excellent Mechanical properties, electrical properties, flame retardant performance and processing performance.

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) | |

| Density | ASTM D-792 | g/cm3 | 1.49 | |

| Shore Hardness D | ASTM D 2240 | -- | 51 | |

| Tensile Strength | IEC 60811-1-1 | MPa | 11.5 | |

| Elongation | % | 185 | ||

| Aging 136℃×168h | Tensile strengthretention | IEC 60811-1-2 | MPa | 13.5 |

| Elongationretention | % | 169 | ||

| Thermal extension(200℃, 0.2MPa, 15min) | Elongation underloading | IEC 60811-2-1 | % | 55 |

| Permanent deformation aftercooling | % | 3 | ||

| -20℃Brittle temperature | IEC60811-1-4 | -- | Pass | |

Combustion performance

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) | |

| Oxygen index | ASTM D2863 | % | 34 | |

| Smoke density | Flaming | ASTM E-662 | — | 65 |

| Non-Flaming | — | 225 | ||

| pH | IEC 60754-2 | — | 5.2 | |

| Electrical conductivity | μS/mm | 2 | ||

| Toxicity index | NES 713-1985 | — | 1 | |

| Halogen acid gas evolution | IEC 60754-1 | mg/g | 0 | |

Others

| Properties | Test Standards | Units | UV XLPE (Low smoke HFFR ) |

| Dielectric strength | IEC 60243 | kV/mm | 35 |

| Resistivity at(20℃) | IEC 60093 | Ω.m | 2.5×10 12 |

| Thermal Shock(150℃×1 h) | IEC 60811-3-1 | -- | Pass |

| Hear shrinkage(100℃×1 h) | IEC 60811-1-3 | % | 1.0 |

Extruder:

L/D ration: between 18:1~25:1 Screw compression: between 1.1~2.0 Single screw thread

Extrusion Recommendation

| Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 145℃ | 145℃ | 140℃ | 135℃ | 120℃ | 100℃ |

Ultraviolet Radiation Cable Crosslinking Equipment: Normal UV radiation cable crosslinking equipment.

Extrusion Speed: Depends on different colors. Especially production rate of blue color reduces.

Comparison Table of production speed and thermal extension of UV cross-linked

low-smoke halogen-free flame retardant polyolefin cable material (For reference only)

| Conductor cross section ( mm² ) | Nominal thickness of insulation ( mm ) | Production speed ( m/min ) | Thermal extension ( % ) |

| 1.5 | 0.7 | 100~140 | 50~100 |

| 2.5 | 0.8 | 80~120 | 50~90 |

| 4.0 | 0.8 | 80~120 | 50~90 |

| 6.0 | 0.9 | 50~70 | 60~100 |

| 10.0 | 1.0 | 30~45 | 60~100 |

Remark: When red, yellow, blue and green master batches are used, the production speed will be reduced by about 10~15%.

Color master batches added quantity should not exceed 0.4%.

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Indoor colored cables——XLPE Product

Caros clientes, não se preocupem com as cores dos seus produtos, a POLYROCKS possui um departamento profissional de correspondência de cores, fornecendo um serviço gratuito de correspondência de cores. Quaisquer requisitos de cor, por favor, entre em contato conosco por e-mail: sales@polyrocks.com .

O foco da POLYROCKS é fornecer serviço pré / pós-venda imediato, temos engenheiros de moldagem por injeção profissionais e engenheiros de serviço técnico para fornecer informações precisas e serviço oportuno. Qualquer dúvida ou necessidade, entre em contato conosco por e-mail: sales@polyrocks.com .

Qualquer dúvida sobre compras, bem-vindo ao entrar em contato com nosso serviço ao cliente, ajuda será fornecida por eles.

Copyright © POLYROCKS CHEMICAL CO., LTD. Todos os direitos reservados |

Mapa do site

| Distribuído por

CONTATE-NOS

FORMULÁRIO DE INQUÉRITO RÁPIDO

*Indique campos obrigatórios