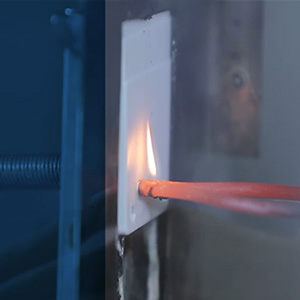

Flame retardant system: Using bromine and antimony as flame-retardant elements.

Main application: Toilet lid material; The antibacterial rate of Escherichia coli and Staphylococcus aureus reaches 99.9%

SGS:ASH19-062458-01

Flammability rating: UL 94 V0

Glow Wire Grade: GWFI:850/3.0

Features: Good antibacterial and anti-ultraviolet performance. Flame retardant does not precipitate, low density, high gloss, strong chemical resistance, low mold corrosion, etc.

PS:We can provide you with free samples for evaluation and test, please feel free to contact us.

Products Introduction: 168M(+)(f1) is dedicated material for toilet lid. The anti-ultraviolet test reaches f1 level and flammability reaches UL94 V0 level. Glow-wire test meets GWFI:850(3.0mm). Good antibacterial and anti-ultraviolet performance. Flame retardant does not precipitate, low density, high gloss, strong chemical resistance, low mold corrosion, etc.

Antibacterial Toilet lid material

Application: Toilet lid material

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

Low halogen FR V0 PP

Flame retardant performance: 168M(+)(f1) use bromine and antimony as flame-retardant elements.

Temperature: GWFI:850(3.0mm); Anti-ultraviolet test reaches f1 level and flammability reaches UL94 V0 level

Characteristic: Good antibacterial and anti-ultraviolet performance. Flame retardant does not precipitate, low density, high gloss, strong chemical resistance, low mold corrosion, etc.

| Properties | Test Standards | Units | Antibacterial & Anti-UV flame retardant PP | |

| Type M2(f1) | Type M3(f1) | |||

| Density | ASTM D-792 | g/cm³ | 1.04 | 1.02 |

| Melt index (230℃/2.16kg) | ASTM D-1238 | g/10min | 25 | 22 |

| Mold Shrinkage | ASTM D-955 | % | 1.3-1.7 | 1.3-1.7 |

| Tensile Strength | ASTM D-638 | Mpa | 32 | 32 |

| Flexural Strength | ASTM D-790 | Mpa | 45 | 38 |

| Flexural Modulus | ASTM D-790 | Mpa | 1500 | 1300 |

| Izod Notched Impact Strength(23℃) | ASTM D-256 | J/m | 25 | 25 |

| Heat distortiontemperature(0.455MPa) | ASTM D-648 | ℃ | 120 | 120 |

| Ball pressure(125℃) | IEC 60695-10-2 | mm | ≤2.0 | ≤2.0 |

| UV stability | UL 746C | - | F1 | F1 |

| Flammability | UL 94 | 1.5/3.0mm | V0 | V0 |

| Glow wire Performance | IEC 60695-2-12 | GWFI:850/3.0 | Pass | Pass |

Remark: The above laboratory test data are just for reference only; it’s not a basis for quality assurance.

Toilet seat

Toilet seat

Toilet seat

Caros clientes, não se preocupem com as cores dos seus produtos, a POLYROCKS possui um departamento profissional de correspondência de cores, fornecendo um serviço gratuito de correspondência de cores. Quaisquer requisitos de cor, por favor, entre em contato conosco por e-mail: sales@polyrocks.com .

O foco da POLYROCKS é fornecer serviço pré / pós-venda imediato, temos engenheiros de moldagem por injeção profissionais e engenheiros de serviço técnico para fornecer informações precisas e serviço oportuno. Qualquer dúvida ou necessidade, entre em contato conosco por e-mail: sales@polyrocks.com .

Qualquer dúvida sobre compras, bem-vindo ao entrar em contato com nosso serviço ao cliente, ajuda será fornecida por eles.

Copyright © POLYROCKS CHEMICAL CO., LTD. Todos os direitos reservados |

Mapa do site

| Distribuído por

CONTATE-NOS

FORMULÁRIO DE INQUÉRITO RÁPIDO

*Indique campos obrigatórios