Flame retardant system: Environmental PP masterbatch with phosphorus, nitrogen, and bromine as the main flame retardant elements.

Product application range: Flame-retardant masterbatch for hollow board/non-woven fabric, can also be used for other extrusion and injection molding parts

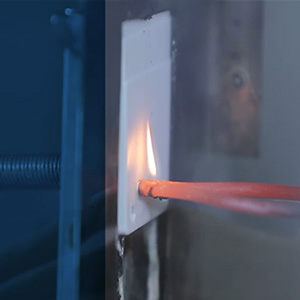

Flammability rating: UL 94 V2

Features: Easy to process and cost-effective, it meets the flame retardant requirements of hollow board/non-woven fabric.

Products Introduction: 5003RM9ST is mixed at a ratio of 4%-6% in homopolymer PP, the flame retardant level can reach UL94 V-2 (1.5mm and 3.0mm), and the bromine content of the processed products after mixing is less than 500ppm; 5003RM9ST is in copolymer PP Mixed in the proportion of 6%-10%, the flame retardant level can reach UL94 V-2 (1.5mm and 3.0mm). 5003RM9ST has passed UL certification and meets the product requirements of RoHS, SVHC, PFOS&PFOA, 17P, PAHs, and other regulations. Products using 5003RM9ST also have the characteristics of the low density of flame-retardant products, low smoke emission, and low corrosion to molds.

FR PP Masterbatch

Application: Non-woven fabric/hollow board.

Multiple certification guarantee

Reach Certification,

RoHs Certification,

ISO9001:2015 Certification,

IATF16949:2016 Certification, etc.

LSZH FRPE

Flame retardant performance: Environmentally friendly flame retardant Masterbatch with N, P, and Br for PP

Barrel Zone Temperature:Typical value-190℃

Characteristic: low density, low smoke, less corrosion to mold etc.

| Properties | Test Standards | Units | Extrusion/injection grade environmental FR PP masterbatch |

| Density | ASTM D 792 | g/cm3 | 1.35 |

| Melt Index (230℃,2.16kg) | ASTM D 1238 | g/10min | 5 |

| Flammability( Mix PP with 5003RM9ST ) | UL 94 | 1.5mm | V-2 |

| 3.0mm | V-2 |

Molding Recommendation

| Process parameters | Typical value | Range value |

| Barrel Zone Temperature | 190℃ | 170~220℃ |

| Pre-Dry Requirements | 90℃,2~4h | |

| Adding proportion for homopolymer PP | 4%~6% | |

| Adding proportion for copolymer PP | 6%~10% | |

Remark: The above laboratory test data are just for reference only; it's not a basis for quality assurance.

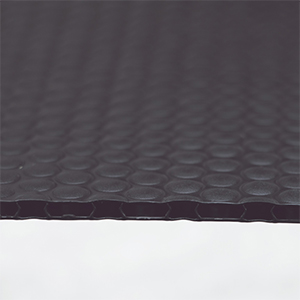

PP hollow board

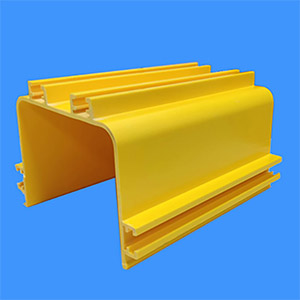

Extrusion profile

Reinforced PP board

Caros clientes, não se preocupem com as cores dos seus produtos, a POLYROCKS possui um departamento profissional de correspondência de cores, fornecendo um serviço gratuito de correspondência de cores. Quaisquer requisitos de cor, por favor, entre em contato conosco por e-mail: sales@polyrocks.com .

O foco da POLYROCKS é fornecer serviço pré / pós-venda imediato, temos engenheiros de moldagem por injeção profissionais e engenheiros de serviço técnico para fornecer informações precisas e serviço oportuno. Qualquer dúvida ou necessidade, entre em contato conosco por e-mail: sales@polyrocks.com .

Qualquer dúvida sobre compras, bem-vindo ao entrar em contato com nosso serviço ao cliente, ajuda será fornecida por eles.

Copyright © POLYROCKS CHEMICAL CO., LTD. Todos os direitos reservados |

Mapa do site

| Distribuído por

CONTATE-NOS

FORMULÁRIO DE INQUÉRITO RÁPIDO

*Indique campos obrigatórios